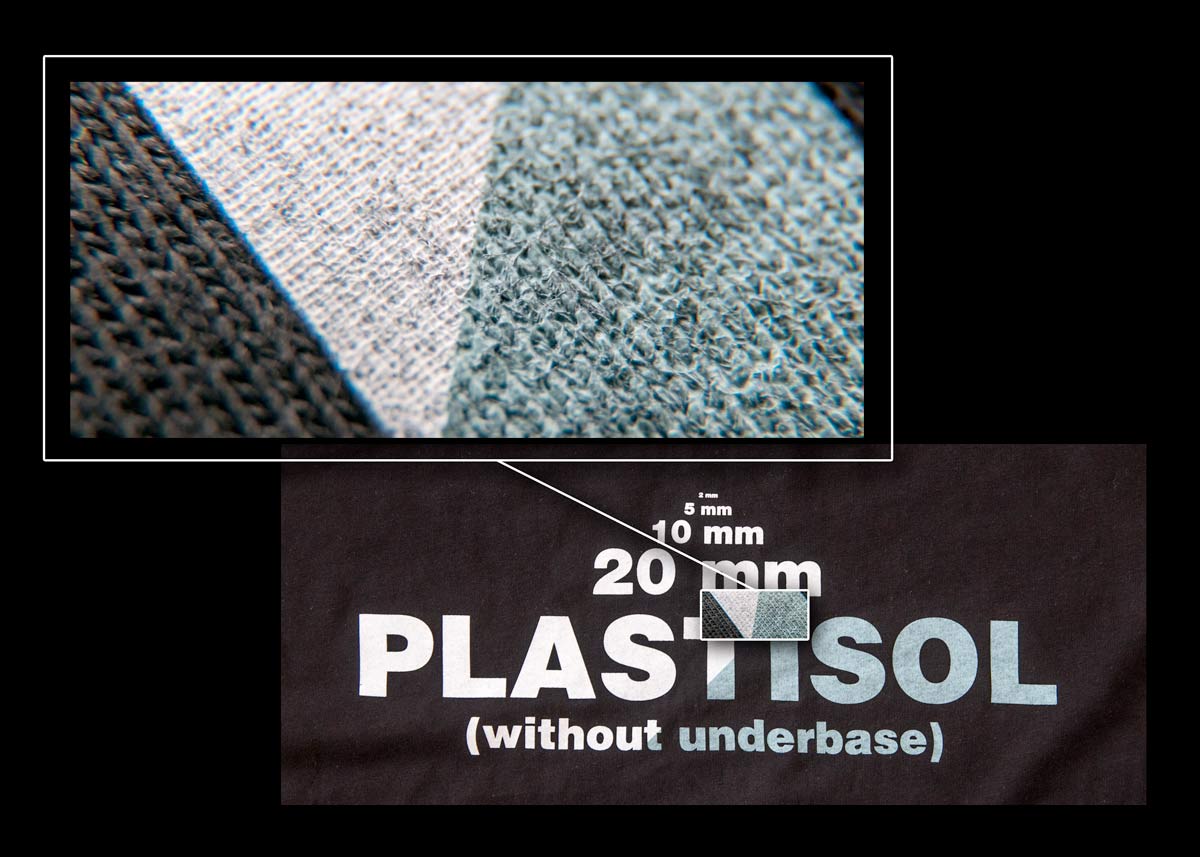

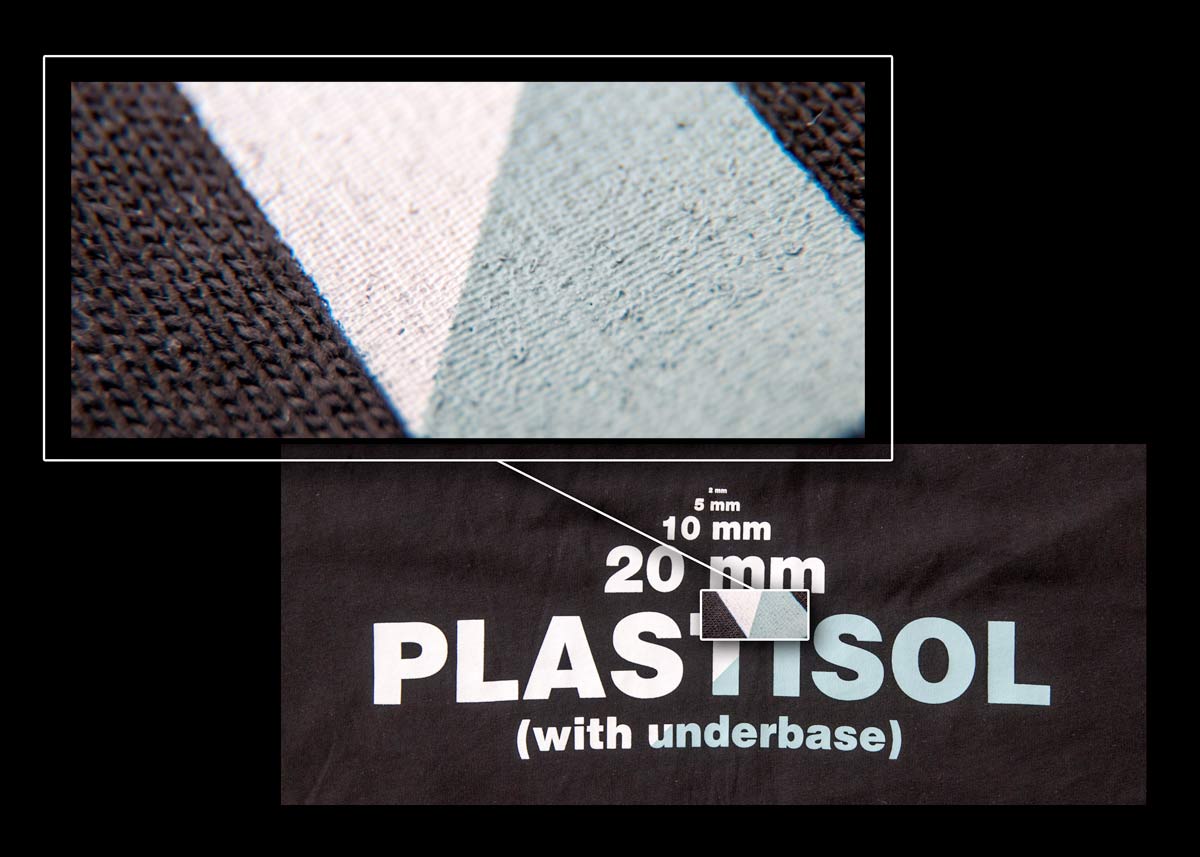

PLASTISOL screen printing without underbase

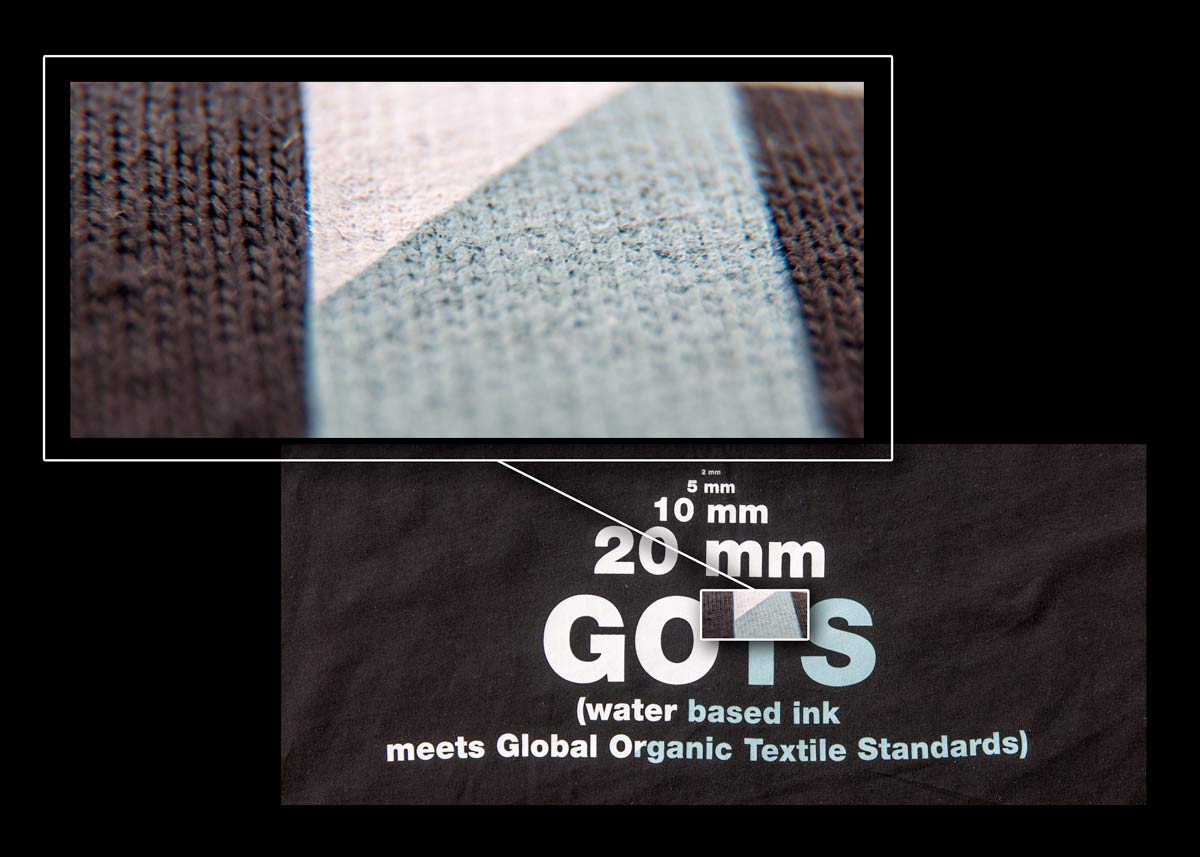

Plastisol inks are used for most standard prints. Printing on white textile without using underbase is standard. However, without the use of underbase on black or other textile colour, the inks do not have 100% coverage. The colour of the fabric we are printing on is partially visible through the printed design.

At MERCHYOU, we exclusively use eco-friendly inks that do not contain heavy metals or phthalates.

Printer's tip:

• This is a great way of printing to achieve a "vintage" effect.

MOQ of 30 pcs per design. Find out more.

• Exact pantone colour shade cannot be guaranteed using this technology.

• Exact pantone colour shade cannot be guaranteed using this technology.